Industrial floor and decking

Whether for technical flooring, industrial walkways, or use in metal processing and construction… Gratings have become an essential flooring elementin structural engineering , civil engineering, and various industries (chemical, petrochemical, energy, food, water treatment, etc.).

Industrial metal grating

Whether as a pressed grating, welded pressed grating or full gratingthe grating can be hot-dip galvanized, KTL-coated, or powder-coated in accordance with EN ISO 1461, depending on the environment and requirements.

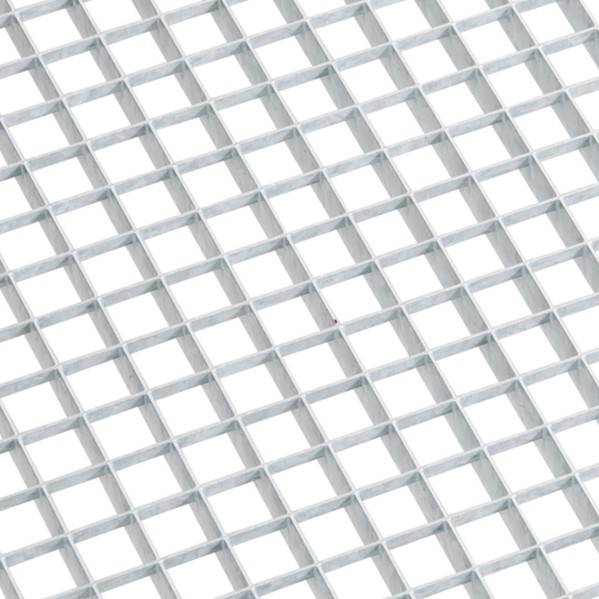

1. Pressed grating

Thanks to their wide range of variants and versatile applications, Pressed gratings offer great flexibility in terms of dimensions, mesh spacing, as well as the height and thickness of the bearing bars.

For more details on pressed gratings for industrial floors and industrial flooring, click here.

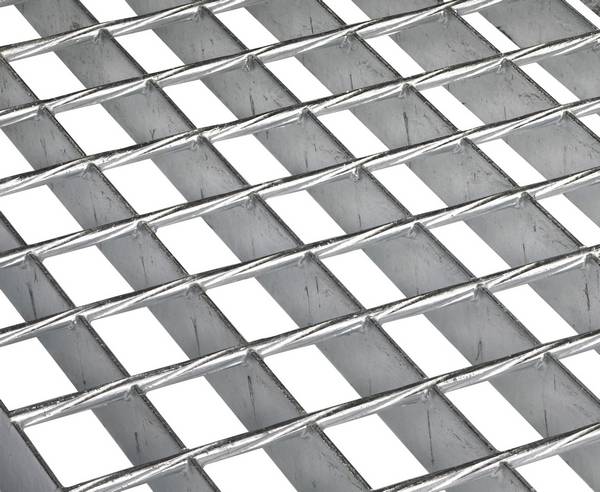

2. Electroforged grating

The welded pressed grating consists of bearing bars into which twisted square cross bars are pressed and simultaneously welded.

The welding at each intersection point between bearing and cross bars provides exceptional stability and strength.

For more details on welded pressed gratings for industrial floors and flooring, click here.

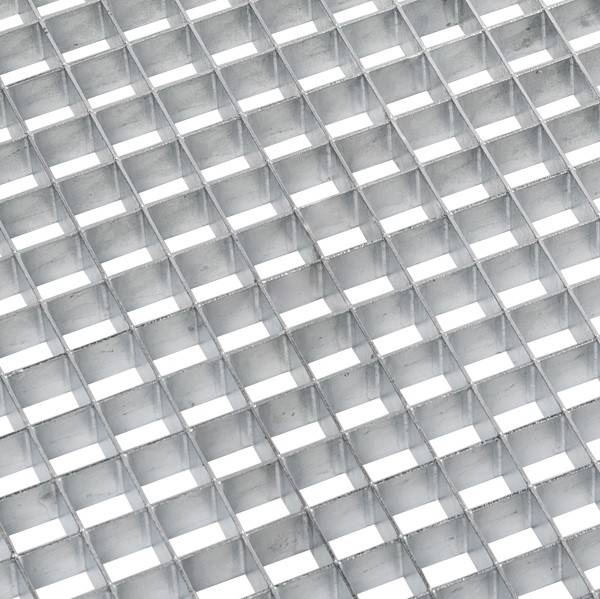

3. Full grating

The full grating as a variant of the pressed grating is characterized by bearing bars (BB) and cross bars (CB) being of equal height. It is often used as a suspended ceiling or railing infill.

For more details on full gratings for industrial floors, click here.

Whichever option you choose, the grating can be designed for barrier-free use with the optionally available safety mesh.

For gratings, the height and thickness of the bearing bars should be selected to safely support and transfer the expected load. For high load capacities, such as with driveable gratings, a Heavy-duty grating is recommended.

2. Safety Grilles for Industrial Floors and Platforms

Thanks to the various patterns, including a serrated surface, the safety grilles from GEI Gitterroste offer an optimal solution in terms of stability, slip resistance, opacity, and liquid drainage.

With its numerous surface variants, the Safety Grilles—whether raw, galvanized, or coated—can be used in a wide range of applications, such as in the automotive sector, industrial construction, scaffolding systems, Stair steps or the outfitting of commercial vehicles.

Manufactured using techniques that ensure consistently high-quality production, these sheet profile gratings comply with current safety standards. GEI Gitterroste’s safety grilles are produced within tolerances according to the RAL-GZ 639 standard.

GEI Gitterroste’s sheet profile gratings are available in various materials and surface treatments to optimally meet your technical requirements and design needs:

- hot-dip galvanized steel (raw or galvanized),

- Stainless steel,

- and Aluminium

The sheet profile gratings depending on the site conditions.

Example below shows the combination of PS-CRANT for the floor and PS-PMR for thresholds and stair steps.

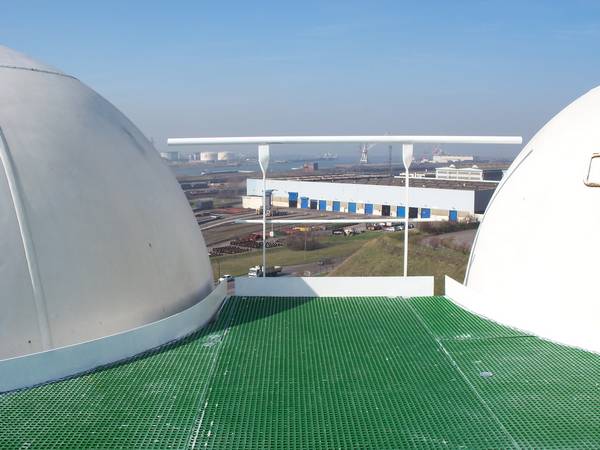

Polyester grating for industrial flooring

Another option for your industrial walking surface—the Polyester Grating

The FRP grating for industrial floors is used in a wide variety of sectors. From the foodand Pharmaceutical industriesto wastewater treatment plants, as well as automotiveand aerospace manufacturing , the FRP grating is the right solution for your needs.

For more details on FRP gratings for industrial floors, click here.