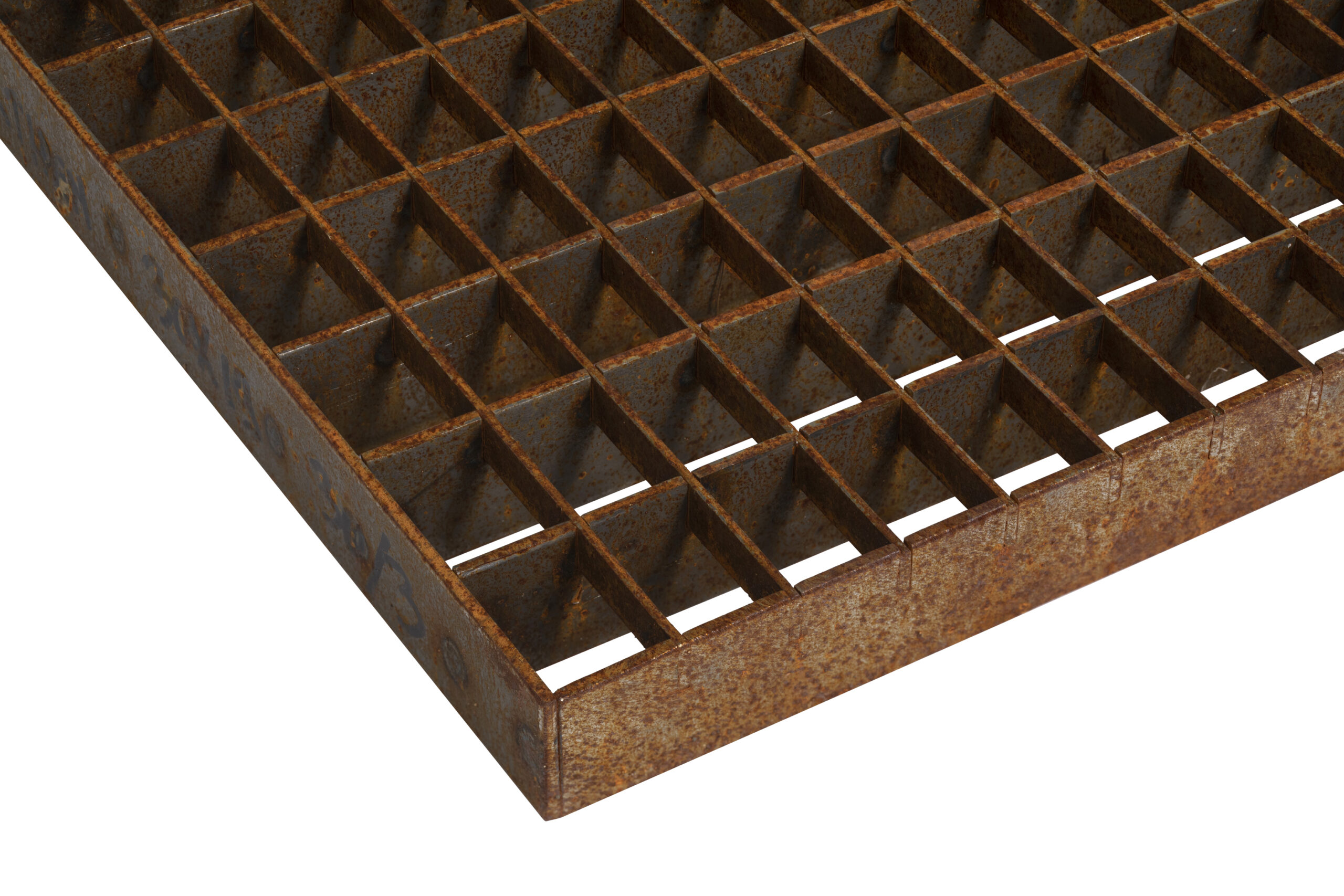

Balustrades and fencing

Press-locked gratings for fencing or solid balustrades are manufactured from galvanised steel, with a powder-coated finish if required. They are quick to assemble and offer good resistance. Whether in stadiums, factories, airports or by private individuals, press-locked gratings for fencing are used in a variety of different contexts. They are available as press-welded gratings as well as slanted-strut gratings for added privacy.

.

- BB gauge: 33.33 mm - 44.44 mm - 55.55 mm - 66.66 mm in 25 / 2.

- TB gauge: 33.33 mm - 44.44 mm - 55.55 mm - 66.66 mm - 99.99 mm in 25 / 2.

- Powder-coated

- Galvanized

- The mesh spacing is defined in accordance with the standards and loads that must be respected:

- For a BB thickness of 2-3 mm:

The BB spacing is typically a multiple of 11.11. - For a BB thickness of 4-5 mm:

The BB spacing is typically a multiple of 18.

The IB spacing is typically a multiple of 17. - Other options are available on request.

- Standard height: 20-150 mm.

- Standard thickness: 2-8 mm

- Other options are available on request.

- Standard height: 10mm

- Standard thickness: 2mm

- Other options are available on request.

- Maximum length of bearer bars: 4000 mm.

- Maximum length of spacers: 2000 mm.

- S235JR steel as per EN 10025 standards.

- Stainless steel 304 ( 1.4301 ).

- Stainless steel 316 ( 1.4571 ).

- AlMg3 aluminium.

- Corten.

- Galvanized in accordance with EN ISO 1461 standards.

- Lacquered in accordance with standard RAL.

- Other options are available on request.

- Available with 'T' or 'flat' edge.

- Available with single or double notching on request.

- Half-moon or sawtooth notching available.

- Custom manufacture based on the dimensions given by the customer or on plans drawn up by our research department.

- Plain or galvanised ½ laps, panels and staircase steps can be easily assembled on site.

Assembly

GEI press-locked grating is characterized by transverse, cross bars inserted under high pressure into pre-existing notches in the bearing bars. This grating is produced in “flat” or “T”-shaped sections, welded into place and then optionally undergoes hot-dip galvanizing in accordance with the applicable EN ISO 1461 standards. For situations with an increased risk of slipping, anti-slip grating can be produced, where the upper surface of the bearing bars and/or the transverse bars can be given anti-slip serrations. GEI press-locked grating is typically manufactured from EN 10025 standard S235JR steel, which ensures a consistent production quality. RAL-GZ 638 manufacturing tolerances applied.xxx

BBs and TBs fixed in place

Press-locking

Application of banding bars